Digital dig boards improve utility mapping capabilities on site

March 14, 2023

No matter the size of the project, utility strikes are always a concern for construction crews, so it’s important to take utility mapping seriously. Hitting a gas, water, or electrical line can not only cause scheduling delays and community disturbances, but it can be a critical safety hazard.

Utility strikes don’t just happen on previously buried lines, though; occasionally, construction crews will hit a utility line that they put in the ground themselves. This issue came to light during a recent regional best practices meeting, and it inspired our team to seek solutions.

“It’s one thing for there to be existing utilities that a crew tries to discover but misses,” said Senior Design Engineer Josh Orton. “And it’s another thing for the crew to have installed the utility and then not know where it is and hit it.”

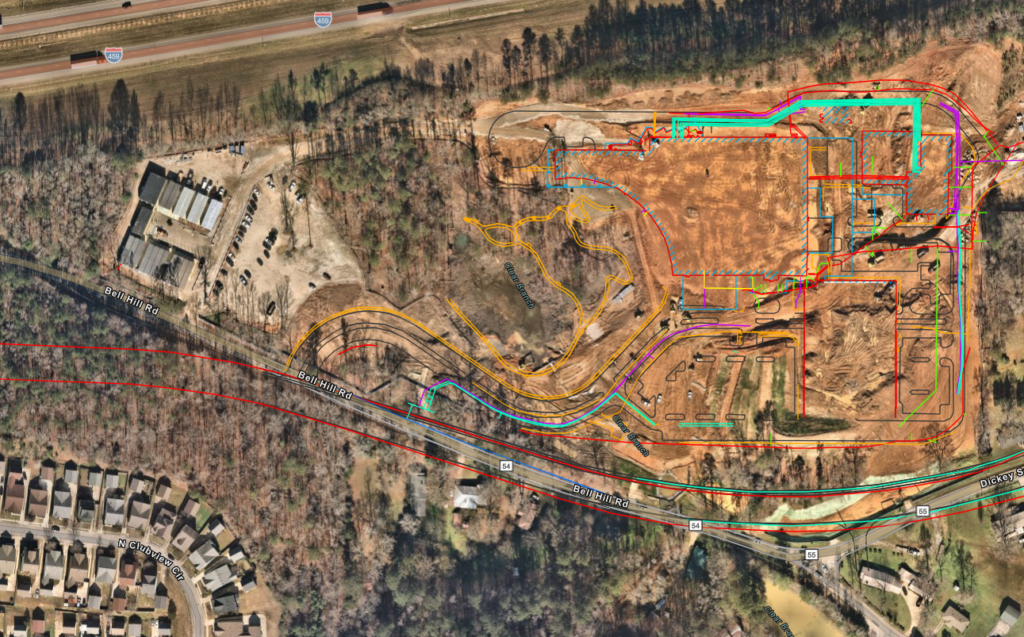

Orton called on intern Sam Lumia—who joined Brasfield & Gorrie full-time in January—to come up with a solution. Lumia created a computer-aided design (CAD) file that could be updated by field engineers on a weekly basis, and then he devised a workflow and directions for converting those CAD files to another file type that’s accessible through Google Maps. To test this system, the team added QR codes to dig boards on an active jobsite so anybody with a phone or a tablet could download the file.

The system proved effective. Using these new “digital dig boards,” field workers could reference the CAD file on their phones to see when they’re within a few feet of a buried line and know what kind of line it was, thus creating a safer and more efficient jobsite.

“We have the QR codes just about everywhere on the jobsite, including on all the digging equipment,” said Field Engineer Luis Ramirez, who is currently using digital dig boards on the Orlando Health project in Lake Mary, Florida. “It’s a much easier process for people to access what’s on the field and what’s underground.”

But there was still room for improvement. Orton collaborated with members of the Innovation and Operational Technology Department to enhance the digital dig board system. The prototype improved accuracy and efficiency, but the CAD files required a good deal of work from the field engineers. Downloading a file straight to a phone also proved to be a messy user experience at times.

The OpTech team’s mission was to take that prototype and convert it into something streamlined and scalable that could be implemented across the company. They moved it from Google Maps to a geographic information system (GIS) using ArcGIS. Users no longer have to download a file—they can simply scan the QR code and view the map straight away. The GIS maps also feature the most up-to-date geographical information to ensure increased accuracy and precision.

“When it comes to changing topography and changing environments, you need the most updated information,” said Innovation and Operation Technology Specialist Kyle Duncan. “We can take these files and put them on a map that exists in real space and time, and we can manipulate that map with more recent satellite imagery.” Thanks to these new and improved digital dig boards, field workers can easily user their phones to see where they are on a jobsite and what’s around them. And thanks to this collaborative effort across multiple departments, our projects have become even safer and more efficient.